Automation of oilfield chemical programs should be economical, secure, reliable and easy.

If done right, it can automate everything an operator routinely does on site to manage a chemical program – not only measure inventory, but adjust pump speed to obtain the desired flow, confirm the flow is maintained over time, and tell you immediately if there is a problem. For some applications, adjusting the dosage with temperature or pressure may be useful. Ideally, the system isn’t cobbled together from multiple separate devices, but is integrated into one unit. The right system can save hundreds of hours of windshield time, provide better control over dosage and provide easily analyzed data on chemical consumption.

Economical

What do Micro-controllers, PLCs, sensors, cellular data plans, cloud storage all have in common? They are commodities and their prices are being forced ever closer to $0. Remember when an ultra-low bandwidth connection cost $45/month, or just a PLC cost $2k? Well, OK, so some people still charge that, but they shouldn’t. Add in secure infrastructure, cloud storage and a basic web app, and it might cost $10/mo. Pick a vendor that charges for the value they add, and not for their ability to resell commodity services.

Secure

An oilfield IIoT device company can be capable of designing secure systems from scratch – if firmware, cloud and web security are within their domain of expertise. That is not the case for most, and even if it is, how much does it add to their costs? Look for a vendor that leverages the skills, and scale-up costs, of certifiable specialists.

What kind of controller do you need? A PLC is simple and secure but has limited capabilities, a single board computer (SBC) is very powerful but may have undiscovered the security holes that come with having a full-fledged operating system. A micro-controller (MCU) with a multithreaded RTOS (real-time operating system) and secure firmware can be the best of both worlds: it can handle large and complex code, but with deterministic execution; it can have both hardware and software watchdogs to ensure reliability and security; and it doesn’t have any code or ports that you don’t specify. The latter is particularly important, as hackers can’t attack something that doesn’t exist. A micro-controller may be capable of hosting a full IP stack, but that is not as secure as limiting communications to a secure tunnel and leaving the internet security to a dedicated IIoT server.

Reliable

We are dealing with all kinds of chemicals in all kinds of weather. Is your solution robust to variations in humidity or temperature? What are the materials of construction, especially in wetted areas? Most polymers aside from PTFE or PFA have incompatibilities with at least one class of chemical. There are applications where FKM (e.g., Viton) seals won’t work and where EPDM will, and vice versa. The easiest and most cost-effective is to design with PTFE and machined 316 SS to avoid those weaknesses in the first place.

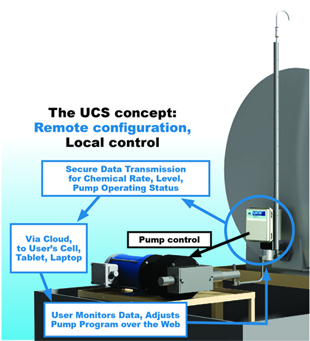

The system should continue doing what it is supposed to even if communications are interrupted for long periods of time. If closed loop control requires a constant stream of data to be sent to a server, which then sends control instructions back, the closed loop can easily be broken. The closed loop logic should be on site and backed up by multiple levels of integrity checking. Wireless communications should be used only for configuration changes and to report data.

Easy

The whole point of automation is to reduce the workload and headaches of routine tasks. If the system requires expensive specialists to install, or if routine configuration requires re-reading a manual, then the automation system isn’t automated enough. Unless tie-ins are needed to other instrumentation, a plug-and-play system is possible. Whether a level sensor or more sophisticated dosage automation, site personnel should be able to connect the device and turn it on. Telling the system what to do, when changes are desired, should be easy as well.

For oilfield chemical programs, the most basic approach is to monitor the chemical tank level, if weekly consumption estimates are good enough. This can work with sufficient flows unless the level indication is unreliable or affected by temperature or humidity (think vapor space ultrasound). If dosage changes are required, an operator still needs to visit the site. Besides, if you are going to go through the trouble of installing a digital device and establishing a communication link, why not automate more and get instant notification of issues?

The top end approach is to automate it all, in a single device. Confirm the actual flow rate regularly. Flow meters can be useful, but they are not cheap and don’t do a good job of integrating pulsing flows. The gold standard for measuring flow from the small pulsating pumps used in these applications is to do a drawdown: fill a calibration column with fluid and see how fast it is emptied by the pump. If it makes sense, tie the target flow rate to a process variable (or variables) so that it feeds the chemical you need, when you need it.

Of course, I am biased towards the top end approach. At Wave Control, we like automation, and making it Economical, Secure, Reliable, and Easy.

Introducing Wave Control’s Uninterruptible Chemical Supply (UCS).

Automating drawdown flow measurement, and then using it for PID control of dosage, is the patented approach we developed and commercialized in the “UCS” system, which can cost less than just a flow meter!

If you have additional thoughts or questions on oilfield IIoT, we would love to hear them.