Process, Controls, and Automation

Our multidisciplinary engineering and design team thrives on technical complexity. Talk to us about how we can incorporate the following elements into your next project:

- Customized process control

- Analyzer integration

- Automation and control packages for general or hazardous areas.

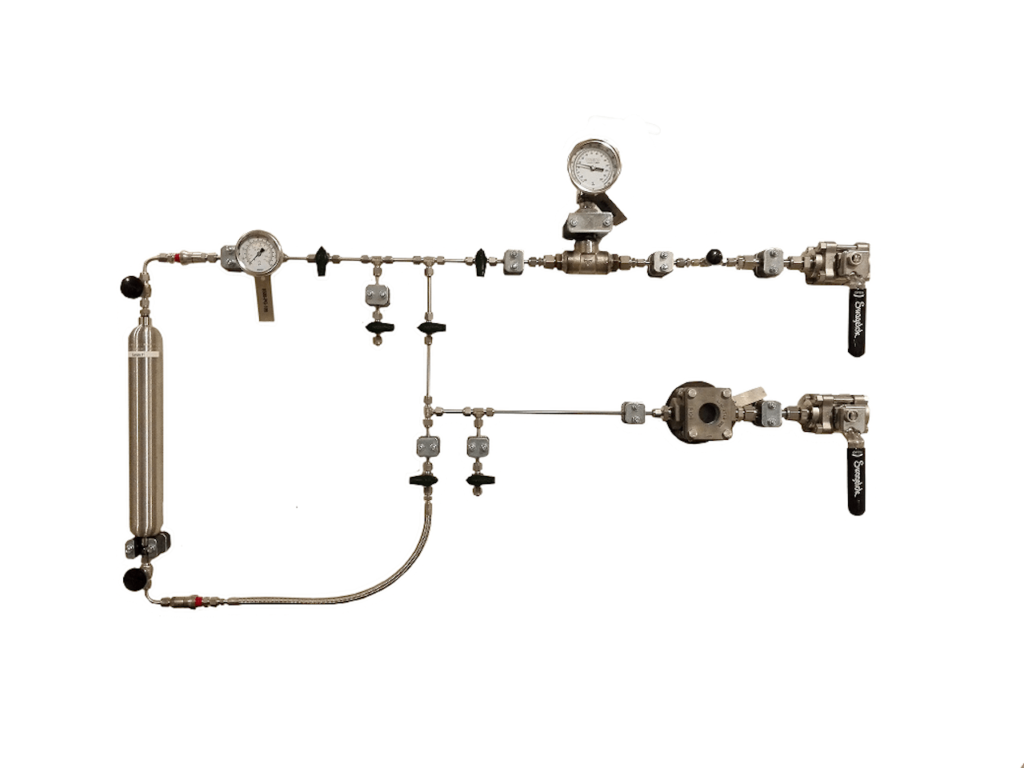

- Sampling and conditioning systems

- E/I, PLC, VFD/inverter, motor/motion control, wireless communication

- Material handling, industrial, and manufacturing motion, vision, network and related automation, control, and communication

- Expedited custom engineered package created for a major global oil producer

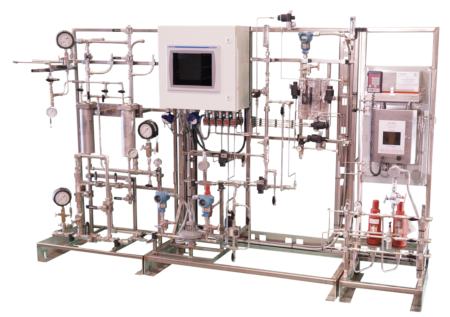

- Specialized analyzer (Gas Chromatograph) sample conditioning and process control package custom engineered, assembled, and tested in house

- Designed and fabricated in collaboration with our client

- Utilizes specially designed process control and automation functionality including but not limited to: heating, cooling, vacuuming, flow, and pressure

- Prepares volatile fluid samples as per specification

- Free issued, general area analyzer integrated into a purged enclosure

- Certified for Class 1 Div 2

- Includes conditioning and measurement equipment

- Engineered for reliability based on specific site process conditions

- Panels and shelters for general and hazardous areas

- Gas purge and blanketing systems

- Precise measurement and control for flow, level, temperature, pressure, and other variables

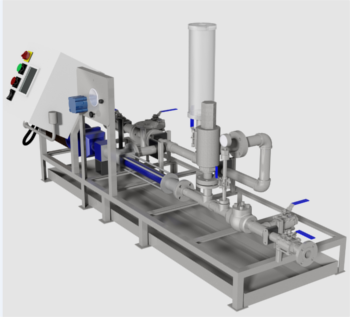

- Customized process control equipment ranging in size from small wall mounted stands to larger Enclosed Package Equipment

- Boiler and process sampling panels and sample conditioning

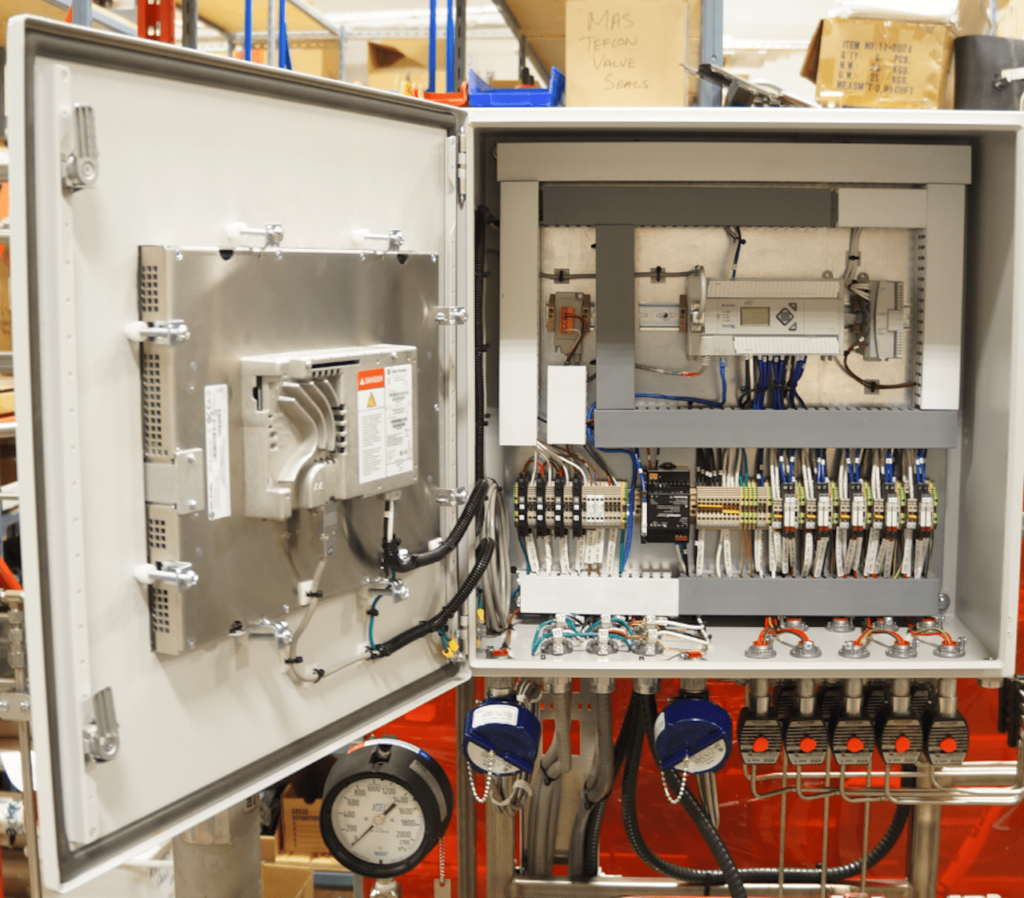

- Touchscreen and PLC Control Panels

- PLC’s and HMI’s are selected based on project requirements

- Custom programmed to satisfy client’s exact requirements

- HMI programmed for easy operator interface and quick intuitive operation

- Variety of communication protocols to transmit data back to client’s DCS

- Can be used for batching, process control, recipe control, skid automation, pump control, and many other functions

- Customized Automation and Control Panels for general or hazardous areas

- Panels can be stand-alone or integrated into packaged equipment

- A variety of PLC brands available, depending on client’s requirements and budget

- Parts and enclosures are selected for a variety of hazardous locations: Type 4 or 4X enclosures, Explosion Proof enclosures

- Capable of interfacing with nearly any combinations of signals: analog, discrete, TC, RTD, serial, Ethernet, etc.

- Can be adapted for interfacing with pneumatic signals

- Includes complete wiring diagrams and drawings

- VFD enclosures for general or hazardous areas